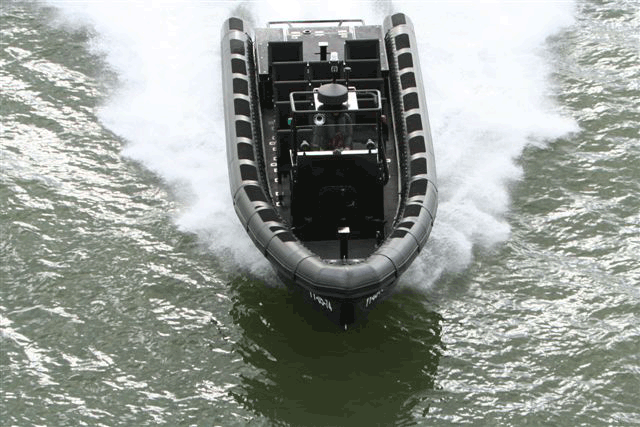

Madera Ribs has extensive experience in the design and build in series of fast RIBs for professional commercial, para-military and military users.

A Madera is redundant, low maintenance and of superb build quality. All this together makes a Madera Virtually Indestructible

The Madera has a superior seagoing behavior in rough seas at high speeds, which is the basis of a successful military and commercial Rib.

The height of the tubes in combination with a high dead rise and a moderate beam insures less vertical accelerations and a smoother ride than a conventional Rhib.

The Madera Rib is handmade by experienced craftsman which results in the strongest Rib on the market. Madera is not cutting corners to save money. To make our hulls even stronger we use extra kevlar reinforcements in traditional areas of stress. We don’t aim also for the fastest and lightest crafts, but the main focus is building the strongest and most robust craft with a superb sea going capability. Only such a craft will survive the most extreme sea states. The Madera crafts are designed and build to stick around.

For some models we use advanced composites as a building material and for other application we offer aluminum crafts. Depending on the application they both h ave their benefits and downsides.

ave their benefits and downsides.

We have a wide experience with Combat boats, air droppable RHIBs, , bullet resistant applications, stealth techniques, boarding platforms, NBC and CBRN solutions, Semi-submersible boats, USV’s, techniques to reduce the radar and heat signature and we even have experience with integrating complex remote weapon and defense systems such as RWS, Torpedo’s and different kind of missiles.

Madera collaborates very close with the major global system suppliers and integrators in their field, but we also work together with local companies and subcontractors.

The Madera crafts can be powered by single, twin or multiple outboard engines, two or more inboard diesel engines with stern, surface drives or water jets. Almost all engines brands and models with a good reputation can be selected and fitted according to the purpose and geographical operation of the craft. For inboard diesel engines we install for example Steyr, Volvo Penta, Cummins, MTU, MAN, Yanmar and Caterpillar. Regarding the outboards mainly install different types of Mercury Verado or Yamaha outboard engines.

Also Navigation and communication equipment can be freely selected by the customer or proposed by us.

We use Imtech Marine & Offshore for the Electricity and system integration. This organization is worldwide known for their high quality installations and their wide spread service organization.

Madera has an In-house design department. Every model is first completely engineered in advanced 3D design software before the start of production. In this way the room for error is minimalized to almost zero.

Only the best materials and parts are used. The whole production process and the production facilities are Fully controlled and certified.

Each model is fully checked and tested for its seaworthiness.

We have an experienced project management team who are used to manage and deliver large quantities of crafts and still meeting all the set delivery deadlines as one of the few in the world.

Our production facilities consist of

State of the Art Composite department of 3000m2

Assembly department of 3500m2

Aluminum department of 2500 m2

Tube department of 500m2

DESIGN

Every successful crafts starts with a successful design

Madera Ribs designs and produces crafts from 6m till 21m with different layout, console, seating and cabin layouts each optimized for their purpose.

The most of our models are based on proven designs, but we also have innovative award winning state of the art designs which are able to set the new standard in military and commercial boating.

Madera uses state of the art Solidworks™ 3-dimensional computer aided engineering (CAD) software to develop the Madera crafts and their components.

Before the start of the production, every model is already detailed designed in 3D. Almost every part is already installed in 3D. This allows the naval architect to precisely calculate the weight, strength stability and speed of the future craft. Also hydrostatic and hydronamic analysis can be carried out by our design department. Next to this theoretical approach we also do many practical tests and mockups in our workshop, to confirm that the software is right. Nothing is left to the unknown.

Madera has an in-house design department with experienced naval architects. Our focus is always to design something which is practical and modular in the field and next to that very robust and fool proof with always keeping easy maintenance, service and repairs in mind so that you will have a virtually indestructible and redundant craft.

As you can see on the right all our real models are exactly the same as their 3D designs. This ensures you, that the craft you buy is exactly the same as the 3D design you have agreed with.

Every craft is designed from the user’s perspective. We interact and work close with the users and customers in the field and use this input to make our crafts even better and really solve the practical problems of the specific users in a specific environment. In that way we stay on target and create a satisfied and returning customer of which we already have many.

We own all the the moulds and the designs of all our models.

Some of the design challenges we already have experienced with are:

-

Designing extreme fast crafts +70 knots

-

Making sure that our crafts are easy transportable. For example a 11m RHIB in a 40ft container, underslung a helicopter, in a C130 etc.

-

Making our crafts air droppable, so that they can be thrown out of the back of a C130 with 3/4 Parachutes.

-

Creating a turnkey modular craft which can be used for mutiple different missions.

-

Integration of RWS and EOIS

-

Integration of missiles and torpedo’s

-

The design of a modular Bullet resistant craft (the MPAC)

-

Making the craft suitable for fast, dry and rough beaching

-

Integration with a mother craft (Single point lift Davit, Ramp)

-

Low thermal and radar signature

-

Low sound signature

- To reduce vertical accelerations

- The Installation of Multiple outboard or inboard diesel engines for maximum performance, low weight, easy maintenance and redundancy.

- Etc

TESTING

All parts which we buy are tested in house, all custom made parts will first be stress tested virtually and later also physically in our workshop, before installed on our crafts. Every day the installed parts will be checked and controlled by the project manager and the test team.

After the Madera craft is ready it will go through a In house FAT (Factory Acceptance Test). Only if the craft has passed the FAT it is ready to hit the water.

All the Madera crafts will be first tested for hours on the river where the HAT (Harbor Acceptance Test) will be done. After the craft has passed the HAT it is ready for the SAT (Sea Acceptance Test). This will be done for at least 2 days in the harsh environment of the North Sea. In these 2 days the craft will be treated and tested in the worst way possible, just to make sure that all the parts are well installed and that nothing will come loose after delivery to the customer.

After the acceptance by the client the craft will be checked again for delivery. If everything is ok, the craft will be washed, cleaned and wrapped for transport.

Madera stands for the toughest and most durable platforms available as a high speed craft. Madera Ribs has extensive experience in the design and build in series of fast RIBs for professional commercial, para-military and military users.

Madera has a In-house design department. Every model is first completely engineered in advanced 3D design software before the start of production.

Next to this theoretical approach we also do many practical tests and mock ups in our workshop, to confirm that the software is right. Nothing is left to the unknown.

Our drive towards innovating has resulted in solutions for the Madera Rib which enhances the effectiveness while reducing the risks for the crew. The Madera is technically advanced and is ready for the future as it can easily be adapted for new technologies and purposes.

For some models we use advanced composites as a building material and for other application we offer aluminum crafts.

A Madera is very strong and very robust, has an innovative design, is redundant, low in maintenance, detailed engineered and of superb build quality. All this together makes a Madera Virtually Indestructible and the best choice for your mission.

The Madera craft is from that moment totally ready for Action !!!